Wie wählt man einen nanokristallinen Kern für die EMI-Filterung?

2023-05-18

Kategorie: Unternehmensnachrichten

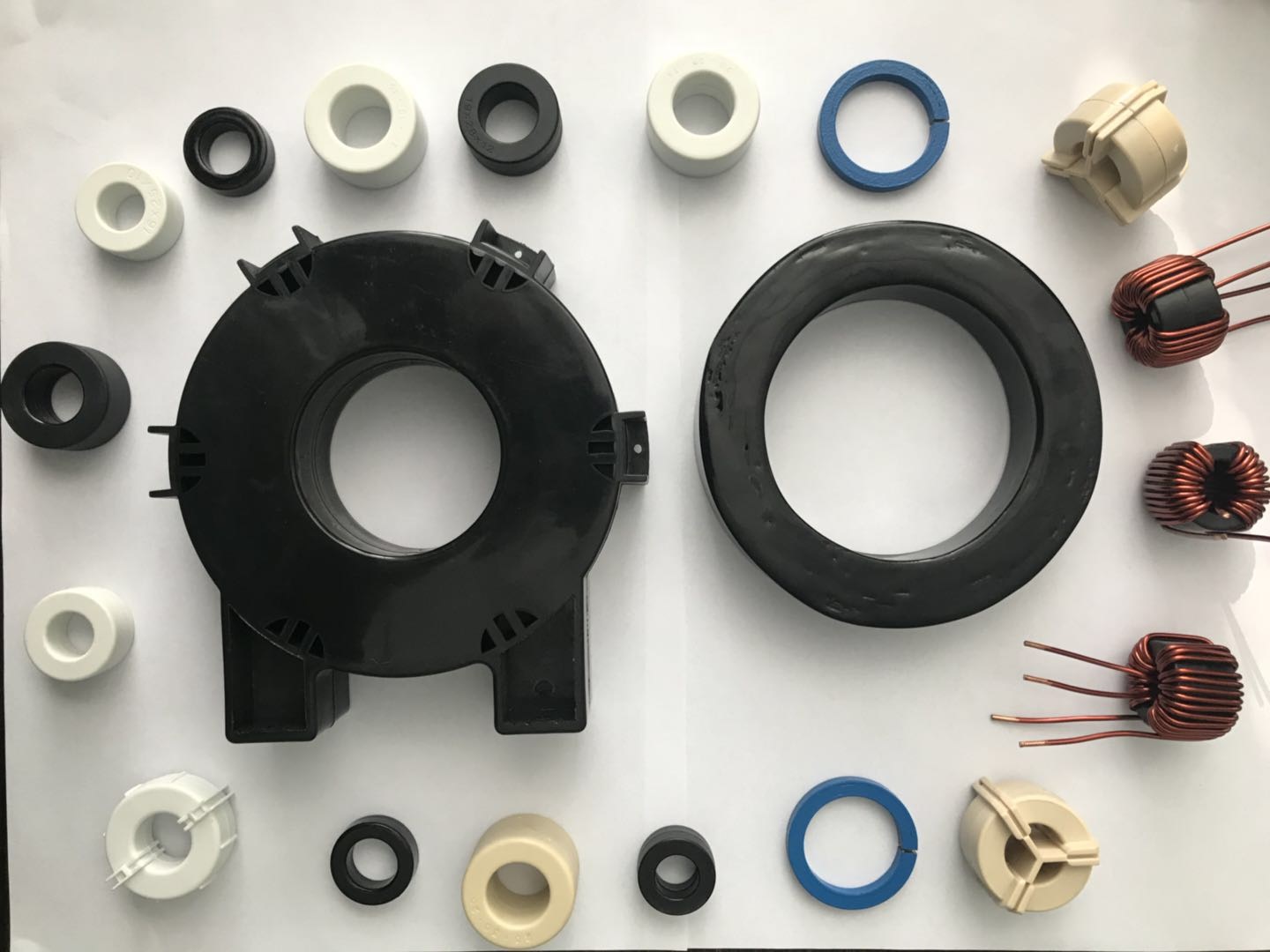

When choosing nanocrystalline core for common mode choke, you should have expected impedance value or inductance value in advance.

Currently, the usual way to do so is to put a large magnetic core( which you already know its diameter) on the cable to test its performance. You can also wrap a few more turns of winding in order to achieve the purpose of increasing the inductance.

Write down the performance specifications (Bs,μ,Ts) that contributed a great EMC performance in the test. Then adjust the core size according to the space of the applied field.

After that, you can directly send us (Email : vina@joinchina.com.cn) the specification of your demands.

When you start an EMC design and involves choosing cores, we recommend you to follow the guideline in below :

1. Start choosing the core at the beginning of your design process

Especially for automotive applications. It happens when the designer lacks attention to EMC until the shell structure and all the hardware structures of the vehicles are finalized, leading to a narrow space available for EMC cores. So the options for EMC were narrowed, making it a problem hard to solve or correct.

1. Must have expected performance value under specified frequency ranges.

JoinChina specification generally presents the inductance requirements under frequencies of 10kHz-100kHz range (Or other requirement please let us know).We can also provide the sweep curve chart of frequency vs inductance for the client’s reference.

2. The larger the core size, the better the performance

Take toroidal core for instance, the core is with an outer diameter of D, an inner diameter of d, and a height of h, its inductance L ∝ h*(D-d)/(D+d)

In other words, the higher the height h of the iron core, the larger the difference D-d between the inner and outer diameters, and the higher the performance.

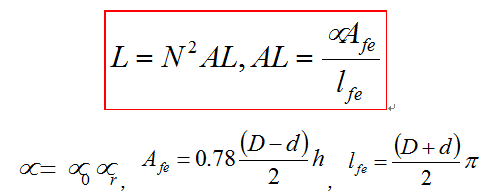

Formula of calculating the inductance value of the ring inductance in below:

L:Inductance(H)

AL:Inductance rating per winding turn

N:Number of winding turns (T)

μ:Permeability(Absolute permeability (H/m)

μ0:Vacuum permeability (H/m)

μr:relative permeability

Afe:Effective cross-section (m²)

Lfe:Mean magnetic path length(m)

D:Outer diameter(m)

d:Inner diameter(m)

h:Height of the core (m)

After core dimension is confirmed, the permeability of the core at different frequency range has become the only variable.

The composition and the thickness of the strip effect the magnetic performance of the core a lot. By using the ultra-thin strips , we can double the permeability of the core comparing with the typical magnetic core in same size. Reducing the core size to half but still remain the same magnetic performance can also be achieved.

4.Choose The Regular Toroidal design if possible

The toroidal shape core can have the largest lamination coefficient, the largest effective cross-sectional area, the smallest effective magnetic path length, and the smallest leakage inductance comparing with the core of other shapes in the same weight, so that the magnetic performance of which is the best.

Talking about the core of other shapes, we have to use external force to flatten and to shape it, and the performance of the core would be attenuated after bearing pressure. The approximate performance attenuation ratio corresponding to the shape of the core are as following:

5.Take the requirement in different applied fields into account

For example, Automotive-grade products have strict requirements on temperature resistance and vibration resistance and so on. The temperature stability of the nanocrystalline core is perfectly suitable that it can continuously work under temperature range from -40°C to 300°C. In that, the protective case for the core is the primary to consider. Currently,Rail-grade products generally use the case made of PA66+30% glass fiber. Moreover, the selection of glue and its dispensing are very important considering the anti-vibration needs of on-board components.

For more discussion, please feel free to contact us at vina@joinchina.com.cn

NEWS

Wettbewerb erfolgreich beendet

2023-05-18

Kontakt

Tel : +86-20-37720102

Cell : +86-13392672318

Email : info@jchncores.com

WhatsApp : +86-15986765253

Adresse: No.18, Suida St. Huangpu District, Guangzhou

Website : www.jchncores.com

Copyright 2023 JCHN Cores